Nell Knives by Chad Nell

Nell Knives are designed, hand made and built by Chad Nell of Nell Knives in Utah, USA

Take a look at some hand made wonders!

Nell Knives are custom hand made knives that can only be created by hand. Knives of all types and styles can always be created in a factory setting - just like anything else. However, to actually produce these custom hand made works of art, it requires a very dedicated and detail oriented person - and a lot of time!

I've been wanting to create a Kitchen Knife set for my family. Once I showed them off, lots of people were asking if I'd make some for the public. Here's a picture of one and you'll find them on our Kitchen Knives page.

Newest Creation ~ Arizona

Arizona ~ 3.25" Blade; 7.75" Overall. Hole Licensed by Spyderco

Trico

Trico Front Flipper with Camo Carbon Fiber from @fatcarbon with Abalone inlay on the pivot and Amoeba Timascus accents

Trico Front Flipper with Camo Carbon Fiber from @fatcarbon with Abalone inlay on the pivot and Amoeba Timascus accents

Examples of various custom knives are shown below

It's an art that just can't be learned from books and the internet. It requires years of apprenticing with great Masters, experimenting and taking the time to acquire that "feel" of producing a product. Only after years of learning and practicing this art of making something with your hands, will that finished product be a true work of art. Custom Knives are just that - a work of art!

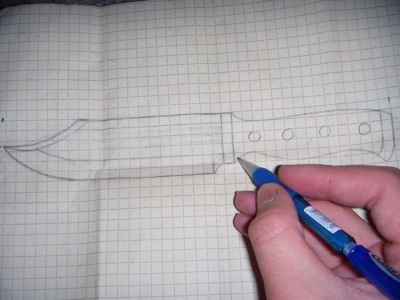

The design of the knife takes on so many characteristics - how does it feel? Is it balanced properly? What type of metal for the blade? What type handle? Is it for show or actual use? How long will it take to make? All of these questions about design and the integrity of the knife itself must be thought of first. The craftsman then has a "look and feel" that the customer wants - Nell Knives.

Transferring that design into the finished product is what makes Chad Nell's knives so special.

Chad considers himself extremely fortunate to have grown up in Central Utah, at the foot of the Manti Lasal Mountains. This is the same area which has produced such world renowned custom knife makers Gil Hibben, Steve Johnson and John Young. Chad is forever indebted to Steve Johnson and John Young for giving him the opportunity to spend time training and working with these two legends, honing his craft and developing his own unique style of handmade custom knives.

Let Nell Knives design, create and be the perfect custom knife maker for you.

Chad will consult with you throughout the entire design process, from the raw stainless steel used, type of single edge blade or double edge blade and of course, your custom handle material. Don't leave anything to chance. Get it right the first time.

Helpful Articles

Knifemaking: “Tricking Out” the Wilton Square Wheel Grinder. By Ed Caffrey ~ BladeMag

The variety and types of belt grinders available today is tremendous. Without a doubt each individual has his/her favorite machine. Although all are very good, we always wish that we could make them do more, or modify them to better fit how we each do things in our shop(s). I have used every grinder out there at one time or another, and have chosen the...Read more....

How to Build a Knife. By Basta ~ Instructables.com

Here's a great article for doing this on a personal level. I'm not here to dissuade you (rather, I'd like to encourage you), but let me first get this out of the way: knife making is a slow, delicate, painstaking, multi-faceted, sometimes frustrating process. It requires skill in metalworking, woodworking and design, patience, attention, and general levelheadedness. You have to take your time if you want to do things right, otherwise your experience will be... Read more....

Knife Making Process ~ By Serenity Knives

Many people have asked how I make knives, thus, I have put together a photo recreation of my knife making process. This is for one of my stock removal or ground knives. I will add the forging process when I am able. A small note on forging: all forging happens before any grinding starts.

This knife is a custom order for a Chef in California, as a congratulations on his most recent recognition. It is a 9 1/2" Chef's Knife, my standard pattern, with a water buffalo horn bolster, Black Ash Burl handle with a white liner, 1/4" mosiac pin in the bolster, and 2 1/4" nickel silver pins. I start with dimensionalized steel, this is 1084 1/8" thick x 2" deep x 48" long. I order steel as close to the finial ... Read more....

Top 12 Knifemaking Tools for the Beginner. By Cratex Tools

Before we proceed to knifemaking tools, we need to explain a few things about the material you are going to use. There are a lot of things you should pay attention to while choosing a knifemaking steel, especially if you are just about to start and make your first knife There are several types of steel used by knifemakers. You need to know at least some basic information about those that are mainly used. You will choose different steel types depending on how you make knives: by stock removal or... Read more....

Knife Encyclopedia. By Joe Talmadge - KnifeArt.com

This very informative article covers all areas of knives and the various terms descriptions. Very thorough! Discusses Blade Shapes, Blade Grinds, Knife Anatomy, Folding Lock Knife Types, Finishing, Heat Treating Terms, Steels ...Read more....

Knifemaking 101: Read This Before You Make a Knife. By Wayne Goddard

My experience has taught me that there’s nothing like digging in and getting started. I’ve often said the hardest part of the most difficult project I ever completed was getting past the decision to get started. Once I get started, it becomes a matter of problem solving and never giving up. The great inventor Thomas Edison wrote, “Many of life’s failures are people who did not realize how close they were to success when they gave up.” I have some strong opinions about how a new knifemaker should get started. I recommend the first knives be made with simple and even makeshift tools. That’s the kind of thing that lets you .... Read more....

General Traditional Knife Terms. By A.G.Russell Knives

On this page I will cover some basic general traditional knife terms. I was working on some of the more complex terms, when I realized that in many of the definitions I refer to the terms below, and not everyone will know them. So I have them detailed out below. Click on the image for a large....Read more....